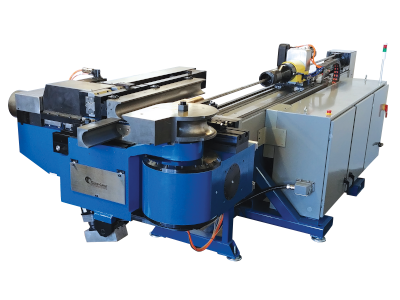

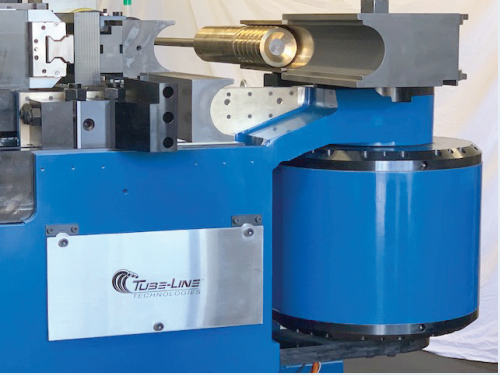

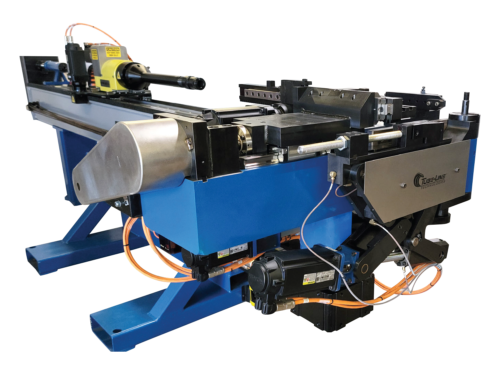

Description

BOSCH-REXROTH MS2N MOTORS WITH INVERTER DRIVES

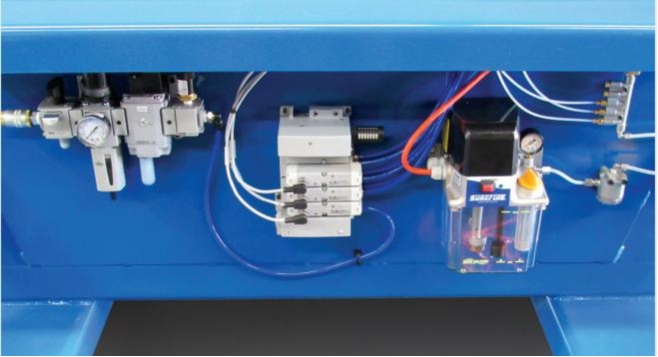

The linear guideways are also Bosch-Rexroth. The I/O is Beckhoff as it is using the BendPro software. The bender has 235,000 in-lbs of torque (ie. a 4.000 OD x .105 WT (mild steel) on a 8″ CLR requires 200,800 in-lbs of torque; a 4.000 OD x .095 WT (304 sstl) on a 8.0″ CLR requires 214,000 in-lbs of torque.)

BendPro G2

Additional Standard Features:

- Program parts while bending

- Multi-part sequencing

- Resume after E-stop and safety zone violation without scrapping the part

- Start bending at any bend number

- Open and closed collet bending support

- Hitch feeding

- Recapture the tube in the pressure die zone using Teach

- Programmable unload sequences using Teach

- Profiling of pressures and speeds

- Feed rate override (0-100% of programmed speeds)

- Electronic gearing of bend arm, carriage, PDA, etc.

- Springback and elongation compensation options

- 24 user-definable alarms

BendPro G2

Available Options:

- CAD interface for importing STEP, IGES, and ShipConstructor files

- CMM interface (Measuring machines including Romer, AICON, FARO, Eaton Leonard Vector, etc.)

- Desktop programming software

- Simulation software (at bender and desktop)

- Push bending (large and/or multiple-radii)