Welcome to our FAQ page! Here, we address common questions about our CNC tube bending machines, ensuring you have all the information you need at your fingertips. If you can’t find what you’re looking for, our support team is ready to help you choose the right machine to fit your needs.

What industries can benefit from Tube-Line’s tube bending machines?

Tube-Line’s CNC bending machines were designed to be simple to use, robust, precise and extremely repeatable for the toughest applications. These qualities are beneficial for an array of industries from space, aerospace, automotive, HVAC, metal fabrication, and any application where a quality bend is needed.

What types of tubes and materials can be bent using Tube-Line machines?

If it could be bent, we have probably bent it. Not only have we bent anything from mild steel to Inconel, but we have even bent Teflon tubing.

Can Tube-Line’s machines handle complex bending requirements?

Our CNC bending machines have a small profile to minimize part shape interference. Also, the teach mode in the software gives the user full control to handle even the most complex of part shapes.

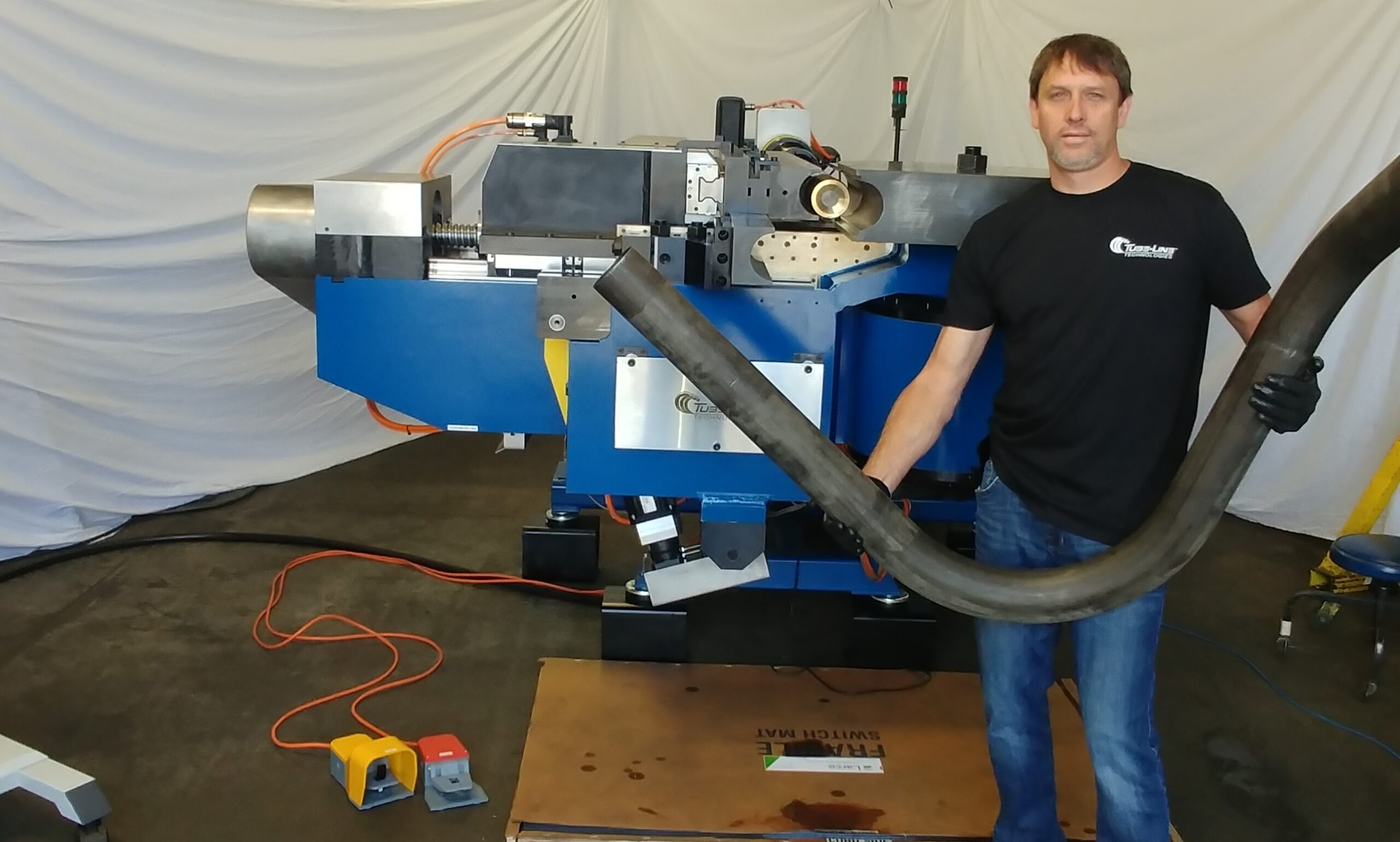

What is the production capacity of Tube-Line’s tube bending machines?

Our CNC tube bending machines currently range in size from 1” OD to 4” OD, but we are always looking for the next challenge.

Are Tube-Line’s machines suitable for both small-scale and large-scale production?

Not only do our CNC tube bending machines provide fast and repeatable cycle times for large-scale production, but our simple and easy tooling change overs mean that you will be bending sooner.

Does Tube-Line offer customization options for specific manufacturing needs?

Our Form-Line series of benders are highly adaptable due to our in-house engineering. We do not create a one-size fits all bender. We have a large array of options depending on the customer’s manufacturing needs.

What kind of support and training does Tube-Line provide for customers using their machines?

Each tube bender purchase comes with 3 days of on-site training. We also encourage customers to send us their most demanding applications and we will proof them out prior to shipping the bender. To further instill confidence in our customers, we recommend they come out to our facility prior to shipping for additional hands-on training and examination of the CNC tube bender.

How does Tube-Line address maintenance and service needs for their machines?

Not only is our manufacturing facility located in California, but we have several service technicians throughout the continental United States. The control software allows simple and reliable remote support. With the ability to send a help email and an ETS file right at the control, a technician can easily pinpoint the root cause of the problem and provide the proper solution.