Description

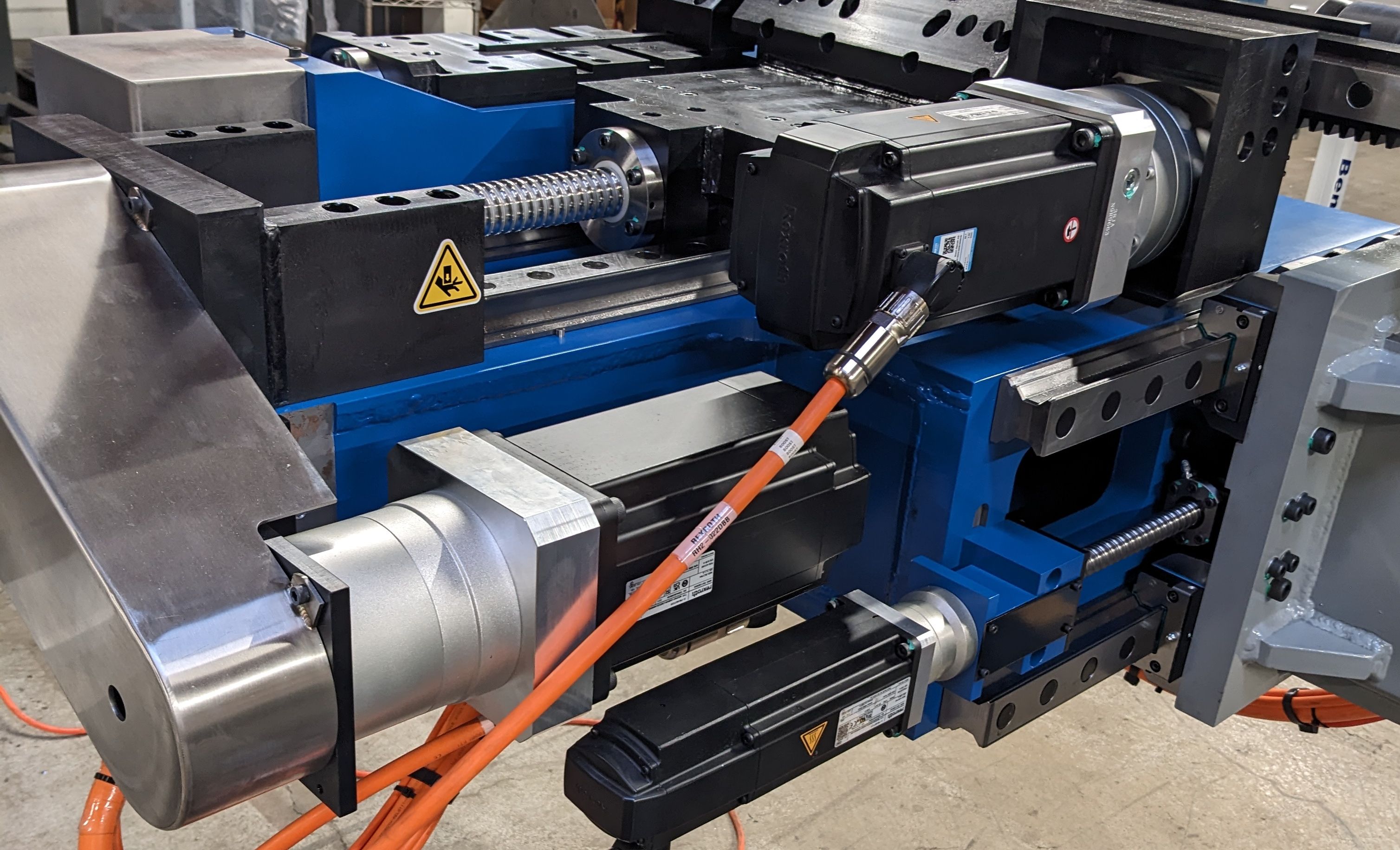

BOSCH-REXROTH MS2N MOTORS WITH INVERTER DRIVES

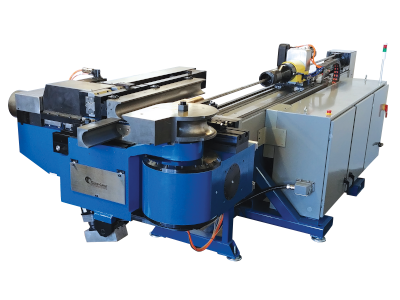

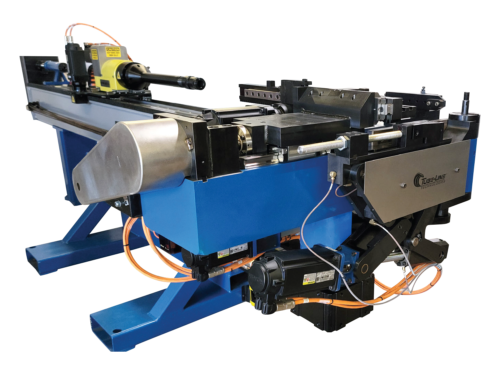

Every electric CNC tube bender from our line of 2 inch tube benders features state of the art MS2N motors, linear guideways, and inverter drives from Bosch Rexroth to ensure that our tube benders have the power and flexibility to bend a wide range of materials.

The Form-Line 2.0 can be configured at 50,000 in-lbs of torque at 32 RPM or 70,000 in-lbs of torque at 26 RPM. (ie. a 2.000 OD x .049 WT (mild steel) on a 2″ CLR requires 45,000 in-lbs of torque; a 2.500 OD x .049 WT (mild steel) on a 2.5″ CLR requires 71,000 in-lbs of torque.)

BendPro G2 Controls and Beckoff I/O

Each tube bender is fitted with a Current Tech BendPro G2 controller allowing every machine to be user friendly while maintaining the highest levels of performance, reliability, and functionality available. The control is additionally paired with Beckoff I/O modules which operate with lightning fast speeds making every machine responsive, and reactive to your needs.

BendPro G2

Additional Standard Features:

- Program parts while bending

- Multi-part sequencing

- Resume after E-stop and safety zone violation without scrapping the part

- Start bending at any bend number

- Open and closed collet bending support

- Hitch feeding

- Recapture the tube in the pressure die zone using Teach

- Programmable unload sequences using Teach

- Profiling of pressures and speeds

- Feed rate override (0-100% of programmed speeds)

- Electronic gearing of bend arm, carriage, PDA, etc.

- Springback and elongation compensation options

- 24 user-definable alarms

BendPro G2

AVAILABLE OPTIONS:

- CAD interface for importing STEP, IGES, and ShipConstructor files

- CMM interface (Measuring machines including Romer, AICON, FARO, Eaton Leonard Vector, etc.)

- Desktop programming software

- Simulation software (at bender and desktop)

- Push bending (large and/or multiple-radii)